Having the task to know what to do with this layout has hung heavy on me. Money never came into it. What had been spent on the layout meant nothing because it gave Darren something to wake up for everyday. As the horrible disease destroyed his body, His mind was still as sharp as ever.

I wanted the layout to continue to mean something to someone. I wanted whoever had it, that they would know what it meant to Darren and they would also cherish it.

There really was only one person to gift this layout to. He is a mini Darren. His love for trains reminded Darren of when he was his age. He was the only person Darren trusted to be in the layout room without Darren also being there. They talk over the internet about all things trains. whenever his dad was coming to visit he would be there as well, politely asking if he could go into the layout room. Daren would speak so highly of this wonderful young man.

When I asked his Dad if I could give the layout to Dillon, I am so grateful that he said yes.

Darren's dream will continue to be cherished. I could not ask for a better home for it.

Thank you Dillon, I know Darren would be so honored that you as the next generation Train enthusiast have his dream to help you grow.

RIP my beautiful Husband , you left us all way to soon.

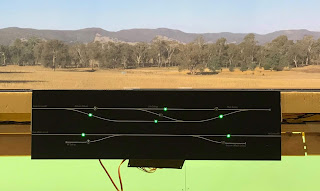

Free-Mo Module Work

-

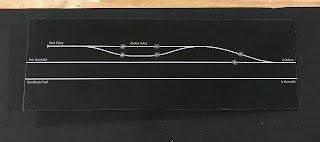

Monday was spent cutting cut up the remaining name tags for the fascias and

placing them were they will go on the layout. I also made the second

length ...

1 day ago