One of the things I like about this hobby, is that it gives the mind a workout at times. I like a challenge, a chance to solve a problem, and when it involves designing and making something of use, that's even better.

With the spare room shelf layout, I've made a decision to hand lay not only the points, but also the track. It was a conversation on a forum about the actual size of sleepers and their spacing on both the NSWGR and Victorian railways and the comparative sizes of Peco, Micro Engineering and Tilig flex track.

I was going to use Peco code 75 which has a nice fine look to it, and probably has the best sleeper spacing to suit NSWGR track, however being essentially a branch line layout, the sleeper spacing would be a little wider than the Peco track. I could snip the spacers between the sleepers and space them out, but that would be rather fiddly.

Another thing that has made up my mind to hand lay is that it gives me the opportunity to use some code 55 rail, which really does look good to my eyes and suits the branch line track work. As a teenager (16yo or so) I attended a modelling convention, possibly at Revesby circa 1986?, and in attendance was a diorama style layout module, Wombat Floor Mills by James McInerney, http://www.cia.com.au/bullack/BL18.jpg.

The track was all hand laid code 55, beautifully detailed with point rodding and light ballasting, and I was very very impressed. It certainly looked a treat compared to my code 100 track of the time, and I remember thinking to myself how nice it would be to have the money and time to have track work like that. Of course the money isn't so much in the track, but in what was basically the need to have expensive brass engines with fine flanges to run on it. James has a web site with lots of info on this fine layout here http://www.cia.com.au/bullack/

More recently, a fellow blogger http://superfreighter.blogspot.com/ has been producing some exceptional looking NSWGR based track and points for his own layout. This is is a classic example of the branch line look that I would like to capture, with the very fine rail and slightly wonky sleeper placement that just oozes old world character.

So with this new aim in sight, the one thing I will need apart from some lengths of rail and some strips of PCB, is a LOT of wooden sleepers. With the branch line maximum sleeper spacing of 2' 10-5/8" (two foot, ten and five eighths of an inch) or 879.45mm working out to around 10mm in HO scale, simple maths says I need around one hundred sleepers per metre. I'm guessing there will be somewhere in the region of twenty five to thirty metres of track to lay, so something like two thousand five hundred to three thousand sleepers will need to be cut!

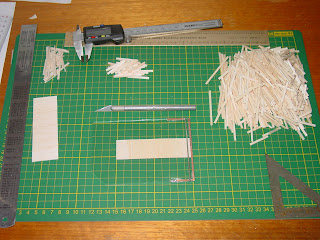

Measuring and cutting this amount of sleepers sounds like a very tedious job indeed if each one has to be measured and cut separately. There has to be a way of making the process simpler and faster. So with a look around the desk, and a bit of thought into it I've come up with a jig for churning out sleepers at a reasonable rate with a minimum of fuss.

I found a small pieces of glass measuring about 13.5 x 9cm, and simply superglued three pieces of PCB to it, two short lengths on each side and a long length across one end. I left a gap between the side and end piece of PCB on one side slightly bigger than a sleeper width.

I then soldered a piece of code 75 rail on top of the side strips a sleeper width back from the end strip. Now all I have to do is cut a single strip of balsa to the width of the sleepers I need to cut, feed the strip under the rail until it is against the rear strip, and using the rail as a guide slice through the balsa with a sharp craft knife cutting the sleeper to width in the process. I can then quickly push it out through the gap between the PCB and then slice the next sleeper to width in a fluid motion.

I found that I can actually cut two sleeper widths of balsa and cut it almost all the way through, so I can cut two sleepers at the same time and simply snap them apart after cutting. I've tried to take a video with my digital camera of cutting a single width bunch of sleepers to illustrate this technique. I'f I'd thought ahead and made the jig a little wider I could cut three widths in

I managed to get over 1,000 sleepers out of a sheet of 100x915mm balsa over about an hour and a half or so which wasn't too bad really. It was certainly worth taking the ten minutes or so to make a simple jig which allowed me to churn out the sleepers at such a rate.

Painting them may take a little longer however and I am thinking about ways to handle this. I'm sure like most other things there are almost as many ways to do it as there are people doing it, and like always any suggestions are gratefully accepted.

3 comments:

Darren, great to see an update.Sleeper cutter is a great idea, seems to work a treat! Enjoy the painting and weathering to come! Thank you for the kind words, although I think you've moved way passed where I'm at, all the best, Geoff.

Hi Geoff

I don't think I'm past you by a long shot, I haven't even got one rail laid yet.

I'm hoping the hobby shop I e-mailed get back to me soon so I can order the rail and get busy. I might have to go old school and pick up the phone!

Cheers

Darren

Hi Darren

What is the thickness of the balsa wood that you use?

Thanks

Shelton

Post a Comment