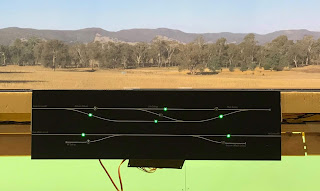

Work continues to progress at a steady rate, the last couple of weeks

seeing the extension of the yard at what is now known as “Anbeon” completed. The

extension of the yard trackwork on this corner module (highlighted in green) consists

of a single set of points with about 450mm of track either side, so nothing

overly complicated.

This corner module already contained the curved track and first set of

points for Gunnedah’s main yard, so it

was only a matter of adding the extra track and set of points, and then

flipping the module over and joining the new dropper wires to the existing bus

wiring.

All of the points on the upper

deck level of the layout are equipped with Cobalt IP Analogue point motors,

made by DCC Concepts, and the point motors are controlled by Alpha Switch A

boards, also made by DCC Concepts. Each board has six outputs, and each output

has the capacity to control two point motors, so you can control six individual

points or up to six pairs of points.

Driving tw0 point motors simultaneous with the press of one button is

handy where you have two sets of points forming a crossover, where you will

always change both points at the same time. The buttons used with the boards

are a very small and neat pushbutton design equipped with an LED, with two

buttons controlling a single set of points, or three buttons when you have two

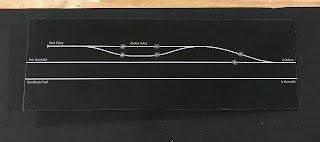

sets of points forming a crossover. So making a control panel with the track

diagram, the buttons are placed on the diverging side of the points, so when

selected the appropriate LED lights up indicating route selection. This is a

very effective system that is very simple to set up as it is literally a plug

and play system.

Whilst there doesn’t seem to be a limitation within reason of how far

away the points can be from the control board (I have tested to a distance of

about three metres), as I am using a modular style of construction, there are a

couple of places on the layout where the control panel and control board will

be mounted on one module, and one or more sets of points operated from this

panel are located on an adjoining module. Because of this the wiring between

the control board and point motor cannot be continuous, so a method of easily

disconnecting the wiring between modules needed to be found.

After doing a fair bit of looking around it appeared that a suitable

style of plug would be a four pin style that is commonly used to power the

small cooling fans inside your typical PC. Looking on eBay, I found that you

can buy twenty centimetre leads with a female and male plug on opposite ends,

with fifteen of these costing nine dollars $9.00 including delivery.

With each point motor controlled by only two wires, each plug can

therefore handle joining two sets of points on an adjoining module. Using them

is very simple, we simply cut each lead in half, strip the insulation off the

end of each wire, strip the insulation from the wires coming from the control

board, twist the wires together, add a dab of solder and then slide some heat

shrink over each joint. The point wiring is then permanently attached on the

underside of each module, with the male and female plug sticking out about five

centimetres from the corners of the adjoining modules. This is enough so the

plugs can be easily plugged and unplugged, and once plugged together can be

tucked back under the modules.

When the point control panels are made with the point motor boards

attached to them, I also want them to be easily disconnected from each module,

so there needs to be a plug to disconnect the boards from the three wire power

bus that runs around the layout framework specifically for the point control

boards, and another plug to disconnect them from the wires going to each point

motor.

The control boards have screw terminals for the main power (three wires)

and point activation wires (twelve wires), but the idea of unscrewing up to fifteen

wires to remove the boards is crazy, so again I spent time looking for

appropriate plugs.

For the three wire main power plug, I ended up using the same style of

plug used on remote control servos, and again these can be bought as short

extension leads with a male and female plug on each end, and if you are willing

to wait a couple of weeks for delivery, they can be bought as cheaply as $2.99 for

ten leads including delivery!

Once again these leads are simply cut in half, one half is soldered to

the main bus wiring running around the room, the other end attached to the

three screw terminals on the control board. This provides another neat and tidy

connection that is very easy to unplug when needed.

That then leaves the actual point control wires that need to be able to

be disconnected when the control panels are removed, with up to twelve wires

needing to be disconnected this time. After looking around I came across what

seemed to be commonly referred to as D-Sub connectors, which are available in a

few different styles, but the ones I chose have screw terminals for fifteen

wires, and a male or female fifteen pin plug (DB15).

These are a more expensive style of plug costing around $9.00 each

(eighteen dollars $18 for a male and female set), but they are well suited to

my needs. The wiring from the control board is run to one plug with all wiring

being colour-coded for identification and tagged where necessary, and the other

plug is located on the appropriate module with the wires from each screw

terminal going to the appropriate point of motor/motors.

As these plugs are bigger and heavier, and sit on the underside of the

modules, I wanted a way of securing them to the underside of the module, but

still make them easy to access and to pull forward so they can easily be

plugged and unplugged. After deciding that most styles of clips or hooks would

be too cumbersome, I hit on the idea of using magnets.

I had purchased ten Neodymium block magnets (19mm x 10mm x 1.5mm) some

time ago, primarily to experiment using them as uncoupling magnets, but figured

if one was glued to the underside of each plug, and then in the appropriate

position on the underside of each module, four magnetic flathead screws are screwed

into the foam module, the plug is quite firmly held in place, and yet can be

easily slid forward to be plugged and unplugged, and then pushed back where the

magnet once again firmly attaches the plug to the screws.

I find that it is definitely worth thinking outside the square, and

looking to other hobbies and forms of technology to find solutions to our model

railway problems.

Cheers

Darren