Panel number two has now been completed and temporarily mounted to make sure it is working as it should, which it all did first go.

As with the first panel I am exceptionally happy with how this one has turned out.

The next panel will feature eleven of the LED equipped pushbuttons, so should look even better again.

Cheers

Darren

Saturday, June 30, 2018

Thursday, June 21, 2018

The First Point Control Panel Completed

The last few weeks have been spent working on getting the point control panels underway. There will be four of these panels located around the layout, and together they will control the thirty-three sets of points on the upper deck of the layout.

The first step of the process involved using a piece of black corflute and some masking tape, which although looking quite ugly, allowed us to get an idea on what kind of spacing was needed for the actual LED equipped buttons to be installed without interfering with each other.

Initially I had tossed up the idea of using some form of thin masking or pin striping tape that would be used to represent the track plan on the various panels, but this would be difficult to do precisely, as well as being incredibly fiddly at best.

I then remembered that Officeworks have a print and copy service, where you can get quite large plans or posters printed. Looking at the website revealed that they do printing on a self-adhesive material, and an A0 sized (841 x 1189mm) poster cost a mere $34.00.

Knowing that the largest panel I needed was just over one meter long, the other panels being much shorter, and each panel being only 160mm high, meant that I would be able to fit all four panels onto one sheet. All I had to do was design the panels.

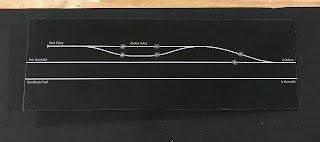

I have used a program called Empire Express Basic to draw the track plans that I have previously used on this blog, and whilst this would not give me the end result I needed, it would give me the ability to do a basic design that would at least have everything looking even and consistent in style.

After doing the initial track plan for the main Gunnedah panel, it was a matter of transferring this design to my photo editing program (Gimp), where I was able to fatten up the lines, manipulate the overall size to fit the panel dimensions, and invert the image from white with black lines to black with white lines.

After the main Gunnedah panel design was completed, I then used various sections to make up the other three panels (basically copying and pasting), this way the design of each panel was consistent.

After all of the line work was completed, it was time to notate the panels, identifying the various sidings, and at each end of the panel identifying where the line was either coming from or going to.

After notating the main panel, I printed it out (as black lines on white so as not to use all of my printer ink) on normal paper, and we stuck it to a test piece of 3mm MDF to see how it looked, and to check button spacing before getting the final designs printed.

This initial print showed that the font size could probably be reduced by about 30%, and I also wasn't completely happy with the font I had chosen. So after spending some time going through a lot of different fonts, I finally found one that I was happy with, and so another test print was done.

Along with change of font, I did some massaging of track plans before the final designs were ready to print. However, before doing the final print on the adhesive material, I had the panel designs printed out on normal paper at Officeworks, which on the same sized A0 sheet was only $8.95. I did is to make sure that the size that it printed was exactly as I needed it to be, and I am pleased to say that it was, and so the final copy was ordered, which basically involves uploading the image to the Officeworks website, and it was ready to pick up the next afternoon, a better service you couldn't hope for.

My wife went to our local Bumnings, and was able to get some sheets of 1200x600x3mm MDF cut down to 1200x160mm, which means that we only needed to cut them to length, which we can measure directly off the printed panel designs.

We started with the smallest panel first which is to control the points for the colliery branch and the two sidings, as this only contains four buttons and is the shortest of the panels.

The other difference with this panel is that the point control circuit board is located about three metres away, mainly because at around $80.00 each it was financially beneficial to run these buttons from the point control circuit board located near the abattoir siding.

As each button has three control wires, and there are four buttons, that makes twelve wires that need to be run about three metres, so I needed to find a way to do this as neatly as possible. Using Cat 5 network cable would have been nice, but it only contains eight wires so that's no good, and then I hit on the idea of using ribbon cable.

Once again looking to eBay, you can buy approximately ten feet or three metres of forty wire ribbon cable for about $9.00 delivered.

The ribbon cable has ten different coloured wires which simply repeat in the same order, so separating twelve wires from the forty wire strip, gave us four sets of three wires with a unique colour code. It was then just a matter of cutting the plugs of end of the button leads and soldering the leads to the ribbon cable. I have ordered some plugs so that the panel can be unplugged from the ribbon cable for easy removal, but they have yet to arrive so that's a small job still to be done.

Once the MDF panel was measured and cut to length, it was given a light coating of satin black apply from a spray can, this helps to seal the MDF as well as making the edges look much neater.

The next step was to cut the panel diagram from the self-adhesive sheet. This was then carefully lined up, and with the backing material peeled away pressed onto the MDF panel.

The next step was to mark out where each button would be located, and then using a six millimetre hole punch, a circle of the adhesive material was easily removed, so that when the drill was used it wouldn't catch on the material and potentially rip or damage it in some way.

The next step was to drill a seven millimetre hole for each button, and then the little bezel that surrounds the bottom can be pushed into the hole and locked into place.

The panel is then flipped over, the buttons lined up in the hole and screwed into place with the small screws that they come with.

It was then time to temporarily locate the panel in place on the front edge of the module, and at the other end of the ribbon cable, plug it into the point switching board. With the point control bus wiring switched on, two of the four buttons lit up as they should, and pressing the other unlit buttons made the correct set of points move in the correct direction. There's nothing quite like being methodical with your wiring, and having everything work as it should the first time.

Even though this is only a small panel, I'm very pleased with the way it turned out, and once in place with the facia panels on either side it should look even better.

The green LED's within the buttons are very bright, and make route selection very clear, and I cannot wait to get the rest of the panels completed.

Cheers

Darren

The first step of the process involved using a piece of black corflute and some masking tape, which although looking quite ugly, allowed us to get an idea on what kind of spacing was needed for the actual LED equipped buttons to be installed without interfering with each other.

Initially I had tossed up the idea of using some form of thin masking or pin striping tape that would be used to represent the track plan on the various panels, but this would be difficult to do precisely, as well as being incredibly fiddly at best.

I then remembered that Officeworks have a print and copy service, where you can get quite large plans or posters printed. Looking at the website revealed that they do printing on a self-adhesive material, and an A0 sized (841 x 1189mm) poster cost a mere $34.00.

Knowing that the largest panel I needed was just over one meter long, the other panels being much shorter, and each panel being only 160mm high, meant that I would be able to fit all four panels onto one sheet. All I had to do was design the panels.

I have used a program called Empire Express Basic to draw the track plans that I have previously used on this blog, and whilst this would not give me the end result I needed, it would give me the ability to do a basic design that would at least have everything looking even and consistent in style.

After doing the initial track plan for the main Gunnedah panel, it was a matter of transferring this design to my photo editing program (Gimp), where I was able to fatten up the lines, manipulate the overall size to fit the panel dimensions, and invert the image from white with black lines to black with white lines.

After the main Gunnedah panel design was completed, I then used various sections to make up the other three panels (basically copying and pasting), this way the design of each panel was consistent.

After all of the line work was completed, it was time to notate the panels, identifying the various sidings, and at each end of the panel identifying where the line was either coming from or going to.

After notating the main panel, I printed it out (as black lines on white so as not to use all of my printer ink) on normal paper, and we stuck it to a test piece of 3mm MDF to see how it looked, and to check button spacing before getting the final designs printed.

This initial print showed that the font size could probably be reduced by about 30%, and I also wasn't completely happy with the font I had chosen. So after spending some time going through a lot of different fonts, I finally found one that I was happy with, and so another test print was done.

Along with change of font, I did some massaging of track plans before the final designs were ready to print. However, before doing the final print on the adhesive material, I had the panel designs printed out on normal paper at Officeworks, which on the same sized A0 sheet was only $8.95. I did is to make sure that the size that it printed was exactly as I needed it to be, and I am pleased to say that it was, and so the final copy was ordered, which basically involves uploading the image to the Officeworks website, and it was ready to pick up the next afternoon, a better service you couldn't hope for.

My wife went to our local Bumnings, and was able to get some sheets of 1200x600x3mm MDF cut down to 1200x160mm, which means that we only needed to cut them to length, which we can measure directly off the printed panel designs.

We started with the smallest panel first which is to control the points for the colliery branch and the two sidings, as this only contains four buttons and is the shortest of the panels.

The other difference with this panel is that the point control circuit board is located about three metres away, mainly because at around $80.00 each it was financially beneficial to run these buttons from the point control circuit board located near the abattoir siding.

As each button has three control wires, and there are four buttons, that makes twelve wires that need to be run about three metres, so I needed to find a way to do this as neatly as possible. Using Cat 5 network cable would have been nice, but it only contains eight wires so that's no good, and then I hit on the idea of using ribbon cable.

Once again looking to eBay, you can buy approximately ten feet or three metres of forty wire ribbon cable for about $9.00 delivered.

The ribbon cable has ten different coloured wires which simply repeat in the same order, so separating twelve wires from the forty wire strip, gave us four sets of three wires with a unique colour code. It was then just a matter of cutting the plugs of end of the button leads and soldering the leads to the ribbon cable. I have ordered some plugs so that the panel can be unplugged from the ribbon cable for easy removal, but they have yet to arrive so that's a small job still to be done.

Once the MDF panel was measured and cut to length, it was given a light coating of satin black apply from a spray can, this helps to seal the MDF as well as making the edges look much neater.

The next step was to cut the panel diagram from the self-adhesive sheet. This was then carefully lined up, and with the backing material peeled away pressed onto the MDF panel.

The next step was to mark out where each button would be located, and then using a six millimetre hole punch, a circle of the adhesive material was easily removed, so that when the drill was used it wouldn't catch on the material and potentially rip or damage it in some way.

The next step was to drill a seven millimetre hole for each button, and then the little bezel that surrounds the bottom can be pushed into the hole and locked into place.

The panel is then flipped over, the buttons lined up in the hole and screwed into place with the small screws that they come with.

It was then time to temporarily locate the panel in place on the front edge of the module, and at the other end of the ribbon cable, plug it into the point switching board. With the point control bus wiring switched on, two of the four buttons lit up as they should, and pressing the other unlit buttons made the correct set of points move in the correct direction. There's nothing quite like being methodical with your wiring, and having everything work as it should the first time.

Even though this is only a small panel, I'm very pleased with the way it turned out, and once in place with the facia panels on either side it should look even better.

The green LED's within the buttons are very bright, and make route selection very clear, and I cannot wait to get the rest of the panels completed.

Cheers

Darren

Subscribe to:

Posts (Atom)